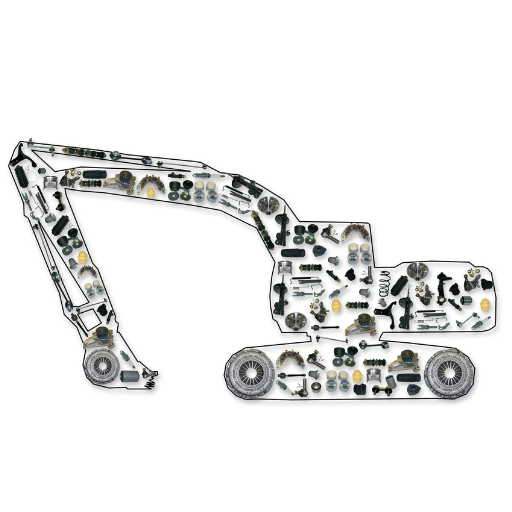

Regarding the construction business, it is no secret that excavators are among the most potent and versatile pieces of equipment. If they have the strength to dig and trench, they can also demolish and do a few operations involving moving sand and concrete. Of course, there is a catch: these machines need regular servicing and timely repairs to be as effective and efficient as they were meant to be. This blog aims to help you understand the essential parts of an excavator that might need to be changed for you to maintain them in a proper work order. If you consider the purposes of different parts, if any part gets worn out and you know it is time to replace the component, the quantity and the extent of risks and delays will be reduced.

What Are the Key Excavator Parts?

Power Plant

The power plant is typically defined as an internal combustion engine. It can also be considered the heart of the machine, as it creates the energy required to drive it. Taking care of the engine is vital since it affects how the excavator operates, while engine service decreases repair costs.

Hydraulic System

The hydraulic system is an excavator’s main working system. It efficiently moves the boom, arm, and bucket and coordinates their actions. This system contains many components, such as pumps, motors, cylinders, and hoses, which need proper maintenance; otherwise, they may cause efficiency or leakage issues.

Tracks or Wheels

Tracks or wheels help to ensure the movement and balance of your excavator. Worn-out treads and tires, which may need to be examined and replaced regularly, help ensure the machine’s safety on site and enhance its mobility.

Boom, Arm, and Bucket

These components are directly involved in the excavator’s digging activities. Inspections are essential and worn out bushings as well as pins need to be replaced to improve the efficiency of the work and also enable great accuracy.

Undercarriage

The undercarriage is classified or distinguished into track rollers, idlers, and sprockets, which are all important in the efficient mobility and functioning of the machine. Regular inspection and maintenance of these components increase the excavator’s performance and life span equally.

Understanding the Basic Parts of an Excavator

In order to appreciate an excavator, it is essential to appreciate the overriding features common with most models. These key elements have been defined in the current top sites on Google as follows:

- Engine: An engine is the main functioning part of an excavator, providing the power for the hydraulic system. It is also crucial for its mobility and performing dealings, which involve boring.

- Hydraulic System: This system consists of a combination of pumps, motors, valves, and cylinders that aid in the hydraulic operation of the machine’s arm, boom, and attachments. Its purpose is to affect the excavator’s overall productivity for various operations.

- Tracks or Wheels: Tracks or wheels, which provide both stability and movement, are parts of the machine that should be continuously monitored for wear and tear. These parts are necessary for the machine’s safe and good performance when working on various terrains.

All three components perform the required duties of an excavator, which is why they are called functions. Intervals of service to each part are necessary to support the machine’s best functioning.

Key Components: Boom, Arm, and Bucket

In an excavator, the boom, arm, and bucket are important parts, each having a particular function. The boom is a structure in the excavator that is seen to be connected to the cabin and is used to lift and reach for the digging and lifting activities. To the boom, there is the arm that pushes and pulls in and out to adjust the distance and position of the excavator shovel. The bucket itself is used to carry out the excavation. This may differ in shape or size based on the work or function being performed such as scooping or trenching and so on. The excavator’s performance can be gauged, particularly through its soil and debris control elements, making it easy to perform various excavation activities. These components are their maintenance practices, ensuring that the Holy can operate efficiently regardless of the working environment and the existing application.

Hydraulic System: Significance and Operations

The hydraulic system is an integral feature of an excavator, as it is responsible for executing any movement or use of energy done by the machine. This system makes it possible to transform the hydraulic pressure into mechanical work to achieve a high degree of accuracy as well as power in the movement of the several parts of the excavator, including the arm, boom, and bucket. Effectiveness in this system works toward providing more delicate and faster response control, which is very important for operations requiring precision, such as in trenching and lifting heavy materials. Periodically performing checks on the hydraulic system, for instance, checking for possible leaks and fluid levels that are often above the base level, prevents loss of time and increases the machine’s longevity. It also fosters all-around efficiency, which is a safety concern on-site.

How to Choose Quality Excavator Parts?

Finding quality parts for excavators requires money and consideration of many aspects such as compatibility, durability, and the brand. The first step is to ensure that the parts are compatible with your particular excavator model so as not to cause performance problems. Second, choose parts made of strong materials that can endure heavy-duty applications. It is also sensible to purchase parts from good manufacturers with a good history of reliable construction equipment. Warranties and reviews from customers should be considered as well in order to evaluate the performance and reliability of the parts. With all these features observed, rest assured that your excavator parts will improve the machine’s performance and lifespan.

OEM vs Aftermarket Excavator Parts

In this case, a number of advantages and drawbacks have to be considered quite closely when deciding which category of parts to use on your excavator: original parts from the manufacturer or ready-made analogues.

OEM Parts means that the original parts are manufactured by the same company that manufactured the unit. These reproductions of original equipment components are manufactured to the same tolerances and engineering controls as the original parts permit proper fit and proper function. Comes with a stress-free warranty and other services, so plenty of worries get alleviated. The downside, however, is that OEM parts are often high-priced relative to parts from the aftermarket.

A large number of Aftermarket Parts are manufactured by third-party companies, which makes the price and quality variance extensive among the spare parts. Such parts are also less expensive and, at times, include features that are absent in OEM parts. However, there is variability in the standards, upsetting compatibility and performance. It becomes imperative to source aftermarket parts from reputable manufacturers and ensure that such parts meet the necessary acceptable technical parameters and performance criteria for your excavator.

Technical Parameters to Consider:

- Material Composition: Both OEM and aftermarket parts should include high-quality materials conducive to heavy-duty applications.

- Load Capacity: It is essential to ensure that the parts will handle the loads and stresses characteristic of your particular excavator model.

- Dimensional accuracy: The measurements of the parts needed to make the assembly should be to the exact size in order to avoid any malfunctions.

- Wear resistance: Determine the component’s ability to withstand deterioration due to wear caused by environmental conditions and usage patterns.

- Warranty: Look into the warranty period and conditions for full-length coverage to ensure the safety of your investment and quality assurance.

These and related aspects have to be contemplated, and the technical parameters must be observed in order to achieve a decision that avails all the performance, cost, and lifetime benefits intended for your excavator.

Identifying Original Parts for Your Excavator

To identify high-quality parts for your excavator, it is worth considering the technical parameters provided by the original equipment manufacturers (OEM) and aftermarket options.

- Material Composition: Quality parts should be grade materials that can withstand the harsh conditions and operations associated with heavy-duty equipment. This guarantees durability and reduces the chances of part failure.

- Load Capacity: One vital aspect to always consider is whether the parts have been tested and approved to handle the different weights and stresses of the excavator model to be used. This criterion is important to prevent unnecessary equipment degradation or catastrophic failure.

- Dimensional Accuracy: Good-quality parts should be manufactured within exact measurements. Dimensional inaccuracies can cause assembly problems, which in turn lead to inefficient machine operation.

- Wear Resistance: Choose parts that are highly resistant to wear and tear due to rough use of the excavator or extreme working conditions. The extent of wear resistance means better service of the parts over longer durations, making them cost-effective.

- Warranty: A piece of equipment that comes with a decent warranty is often a good purchase because it suggests that the original equipment manufacturer is confident in the quality of their product. The warranty safeguards the investment and also gives peace of mind about the part’s sufficiency.

- Manufacturing Reputation: Understand the manufacturer’s background and reputation. Reputable manufacturers that have been in business for a long time tend to have quality components that better serve their customers and produce satisfactory products.

Considering these parameters will help you make the right choice of parts that will improve the effectiveness and durability of your excavator while maximizing its performance regardless of the conditions in which it is placed.

Volvo and Caterpillar Excavator Parts: An Analysis

In a bid to compare Volvo, special attention should be given to the areas that are judgeable in terms of current industry trends derived from equipment developments. Caterpillar parts are well known to be durable and apply the most advanced technology, and they tend to set trends in the market. A plethora of their aftermarket products are available, and it is made sure that they are tested for fit and performance. However, the quality of material used for manufacturing Volvo parts is quite high, and an additional warranty on various aspects greatly helps: one day, you will forget it, and the parts will stand long and perform well. As an industry that embraces sustainability, Volvo integrates environmentally friendly practices into its parts development process. Both manufacturers have long created powerful global hubs for parts sales, and this means that post-purchase and during the life tenure, the end customer will always have a free flow of necessary consumables. At the end the difference in use of parts from Volvo and Caterpillar meat one’s operational characteristics, preference and financing abilities.

What is the Role of the Undercarriage in Excavators?

The undercarriage of the excavator is the most essential part of the machine. It bears the machine’s weight and provides steadiness during working hours. The undercarriage consists of such vital details as tracks, rollers, idlers, and sprockets, where every part is necessary for motion and support. The undercarriage helps the excavator to move from one point to another, irrespective of the nature of the land, because it enables the machine to distribute the weight of the excavator uniformly. With the knowledge that all of these parts of excavators play an important role in maintenance, its regular maintenance is inevitable to ensure maximum efficiency and functionality of the machine for the extensiveness periods possible and also avoid overuse of these parts resulting to costly repairs. This main frame or bottom frame is also important for working uses of the excavator such as lifting, digging work or other heavy machinery work will be able to control the weight.

Components of the Undercarriage: Rollers and Sprockets

Sprockets and rollers are user’ groups that are essential parts found in the undercarriage of any excavator since they perform different and vital roles. The purpose of the rollers is to carry the weight of the machine and to prevent the tracks from going out of the wheel’s plane by making it possible for the weight to be evenly distributed over the terrain. This distribution assists in reducing the amount of friction, hence allowing more fluid motion and efficiency. Tracks, however, have sprockets for engaging with the track chain and driving the tracks around to make advancement, thus converting engine powers into movements. Both of these components are important and must be in good working status, since deterioration or inaccuracy increases the chances of damage and lowers the efficiency as well. Because they get a lot of wear, it is essential to keep an eye on these parts and change them out when they get too old, so the undercarriage’s overall stability and return functions are not impeded.

Keeping Your Excavator Undercarriage In Order

In order to preserve the undercarriage of the excavator, systematic evaluations must be performed, and regular upkeep must be provided. To start this maintenance process, the undercarriage should be washed regularly so as to eliminate the build-up of dirt and other lives that may cause damage. Ensure that the right amount of tension has been given to the tracks and that any necessary adjustments can be made to avoid slipping or over-stretching the same. Look closely at the rollers, idlers, and sprockets to determine the extent of wear and replace any severely worn-out components. The certain parts in the moving machines cannot avoid rubbing against one another, and to reduce this friction and prolong the life of these parts, lubrication should be done according to the requirements. When these maintenance measures are carried out in the required time, the undercarriage is bound to improve, expensive repairs will be avoided, and the efficiency of the excavators will be at their best.

How to Rebuild Excavator Components?

Each step ensures that the scopes of the various excavator components being repaired are brought back to an acceptable operating level. Start with careful disassembly of the defective part, making sure that you do not miss any of its components or their orders. Evaluate all the parts for wear and tear and determine which must be replaced. All the parts and internal surfaces of the isolation must be appropriately cleaned. In the course of the cleaning, any worn-out parts should be replaced with other parts that the original manufacturer of the component accepts to ensure perfection. The components should be put back in their places accurately so that all moving parts should be oiled according to the manufacturer’s instructions. Before deploying the rebuilt part into the excavator, do a reliable check on it to see when it is functioning as it should. Thus, no metric technical aspects are making it easier to adhere to determine these fulfillment to them, and how they are working efficiently in performing.

Step-by-Step Guide to Rebuilding Hydraulic Cylinders

- Preparation and Disassembly: Preparation involves allocating time and space requirements for each stage of preparation and allocating the cylinder in a clean area. Release pressure or any other necessary procedure from the cylinder and remove it from the equipment. Beginning at the lug, work to remove all of the components from the cylinder and place them out in sequence for easier reconstruction.

- Inspection: Close the lock and slide the barrel forward, focusing on the seal, and inspect it closely for visible scratches. Thoroughly assess the cylinder bore, the piston rod, the seals, and the remaining cylindrical components for galleros cracks. In particular, understand that most scars reside on the surface of the rod, which is exposed to unnecessary friction.

- Cleaning: All items should be soaked or scrubbed in a solvent to remove any dirt, grease, or debris. Ensure every last particle is washed away, for any contaminants may help speed the wear of the new seals or any other replacement items.

- Replace Seals and Worn Parts: Determine defective and/or missing seals, O-rings, or any other components and replenish them with new ones. Use an OEM replacement kit; otherwise, it is very unlikely that every part will be fitted correctly and performance specifications retained.

- Reassembly: After cleaning and checking the parts of the cylinder, it is reassembled in the opposite manner to how it was taken apart. Lubricate areas that are supposed to move and where lubricants are needed. Make sure that all parts are fitted securely and in their proper alignment.

- Testing: The hydraulic cylinder is tested for leakage and operational smoothness in suitable conditions after assembly. After the final operational test, the cylinder is mounted back into the equipment to check whether it is working normally in the system.

Following these steps will help you repair a hydraulic cylinder and ensure that it operates smoothly for many more months.

Reconstruction of the Excavator’s Boom and Arm

A well-coordinated approach is key to reconstructing an excavator’s boom and arm. Begin with disassembling the excavator’s boom and arm, ensuring that all the hydraulic hoses and connections are labeled for easy fixing later. Check the parts for cracks, bends, or other wear that may compromise their structural integrity. Any worn-out or damaged parts must be replaced with right-hand quality materials that fit into OEM for endurance and quality. With regards to reassembly, hands should be positioned and held in such a way to ensure the right relations. These include replacing the removed parts on the excavator, changing the hydraulic lines, and performing a function test for regular operation. With the application of constant care, the life of the excavator’s boom and arm of the device will be increased and so will the productivity as the periods for downtimes will be cut.

Inexpensive ways to Rebuild

When considering inexpensive ways of rebuilding heavy machinery such as heavy hydraulic cylinders, the boom, and the arm of an excavator, a thought process where both materials and processes are targeted is a prerequisite.

- Material selection: Most suppliers offer high-standard aftermarket components that are equal to or better than OEM products. Materials like heat-treated steel and reinforced alloys can, in some instances, be cheaper than original equipment replacement parts but as strong as the original.

- Technical Parameters: Make sure that the material hardness, tensile strengths, and corrosion resistance have been tested and confirmed. Specifically, steel with a tensile strength of at least 1200 MPa should be chosen to withstand any operational stresses.

- Labor and Tools: Consider in-house rebuilding if it’s possible, i.e., if skilled labor and the requisite tools are available, as it cuts labor expenses immensely and by a good margin. Some multifaceted fixation or multipurpose tooling has to be brought to reduce the overhead cost in the future as due to most economically no need for specialized apparatus and tools.

- Routine Maintenance: By maintaining an effective maintenance practice, one can reduce the wear and tear rate by replacing components before they are worn to a dangerous extent that can lead to a total malfunction. Avoid the drudgery of mending equipment that has been chronically painful; use predictive maintenance tools to ensure that modest problems never grow large.

- Supplier Relationships: Good suppliers must be sourced, and relationships must be built with them. Eliciting encouragements such as bulk auction discounts or loyalty programs can save costs, especially for relevant parts and materials.

In this manner, it is possible to execute a low-cost rebuilding sequence without loss of effectiveness and to improve the operational capabilities of the equipment and particular machinery.

What Are Common FAQs About Excavator Parts?

Available Construction Equipment Parts Q and A

What parts of an excavator are the most crucial to service?

The customer must also pay attention to the hydraulic system, which drives the digging arm and controls the different attachments or tools. Maintenance of hydraulic fluids and seals or hoses is important. The undercarriage, such as tracks, sprockets, and idlers, also needs regular checking and attention to curb wear.

How long is too long to maintain excavator parts?

The length of time it takes to replace parts depends on the part. For a hydraulic hose replacement, this is between 1000 and 2000 hours of further operation, whereas the undercarriage parts tracked may last between 1200 and 2500 hours, depending on the conditions and maintenance. Following the manufacturer’s instructions on maintenance will give more behavioral aspects.

What technical parameters shall be followed when ordering new spare parts?

Be sure that critical measurements such as tensile strengths, hardness of materials, and internal fitting arrangements are observed. The pressure rating of the hydraulic hose should not be lower than 4000-6000 PSI as that is where excavators operate. Bulk material is also highly dependent on wear parts, such as bucket teeth, and should be tempered with high manganese steels or equivalent for heavy-duty use. It is very important to say that all the parts used afloat maintenance follow OEM guidelines.

By addressing the above common questions, operators are in a position to make sound decisions about maintaining and replacing excavation parts and rods, which suitably increases the productivity and lifespan of the equipment.

Which parts are more suitable for an excavator than others?

Regarding determining which spare part is correct for the zebra excavator, factors such as spare part compatibility and spare part technical parameters and quality must be considered. Here are some straightforward steps to help you out:

- Read the Manual and the OEM Maintenance Recommendations: The first step is to acquire your excavator’s user manual and the OEM maintenance recommendations. These documents contain technical specifications and index part numbers required for compatibility with the machine.

- Peruse the Internet Inventories: Things online such as Parts.Cat.com, MachineryTrader.com and MyKomatsu.com have gone a step further and allow users to search for a target part by part number, machine model or specific system components through a huge online inventory. Using these resources can help check that the parts you are about to order will fit the specified brand and the type of your excavator.

- Consider Reputation and Standards: Order parts only from the right suppliers or manufacturers who follow the Original Equipment Manufacturer (OEM) standards. Adherence to these standards implies adherence to the durability and performance specifications of the parts, such as the tensile strength of hydraulic parts, the hardness of wear parts, and even the operating environment of the parts.

- Pay Attention to Specifications: For instance, when choosing a hydraulic hose, make sure the hose’s specifications have working pressure ratings within that of your apparatus, mostly between 4000 and 6000 psi. It is also important for undercarriage parts or bucket teeth to be manufactured from high-manganese steel or other comparable materials for strength and durability.

By utilizing these procedures and searching online, people can easily locate the necessary parts, which will be helpful for operating an excavator and will ensure the equipment’s prolonged usage.

What Are the Signs of Worn-Out Excavator Parts?

As per my observations and studies, some of the signs of worn-out excavator parts are a reduction in the degree of performance and efficiency such as a decrease in the speed of working or the digging power of the equipment. I usually start to find more vibrations or even unusual sounds when they start working, this means that there is something which is wearing out or even damaged. Visual examination can show problems such as cracks, deformation, or breakage on crucial parts of bucket teeth and hydraulic hoses. An observation of drawings with hydraulic leaks at the seals, or low levels of hydraulic fluids could indicate a disarray with the hoses or seals. Keeping an eye on these signs helps me maintain my excavator at its highest efficiency and prevents unnecessary going down of the engine.

How to Look for Excavator Replacement Parts Redeemers?

After going through the current searches over the Internet, it is clear that several reputable companies sell parts for excavators. eBay and Amazon are prominent websites that stock many parts, both brand new and used, and supplemented, in most cases, with customers` reviews on the quality of these items. However, for customers who want only authentic parts, after-market parts are also found on PartsCat, where there are parts from the manufacturers directly. Another such source is RockAuto, which has a vast amount of parts for many different makes, some of which are reasonably cheap, so I do not have to pay more than what the parts cost.

FAQ

Q: What are the most common excavator parts needed for maintenance?

A: Common excavator parts needed for maintenance include hydraulic pumps, trackpads, final drives, and the cab. Ensuring these parts are in good condition helps keep your construction equipment running efficiently.

Q: Can I find John Deere excavator parts easily?

A: You can typically find John Deere excavator parts at various parts specialists and dealerships. They offer a range of new aftermarket and OEM parts to keep your excavator equipment up and running.

Q: What is the purpose of the excavator’s cab?

A: An excavator’s cab is designed to protect the operator and provide a comfortable working environment. It houses control systems and offers job site visibility, enhancing safety and efficiency.

Q: Are there cost-effective options for parts like track pads and hydraulic oil?

A: Cost-effective options like track pads and hydraulic oil are available for parts. Many suppliers offer aftermarket options that can be more affordable than OEM parts without compromising quality.

Q: How can I ensure my excavator is tipping during operation?

A: To prevent your excavator from tipping, operate on stable ground, avoid overloading the machine, and properly use the counterweight. Regular maintenance of parts like the final drives and track chain links improves stability.

Q: What types of excavators are compatible with Komatsu and Hitachi parts?

A: Komatsu and Hitachi parts are specifically designed for their respective excavators. If you have a Komatsu or Hitachi excavator, you should use parts that are compatible with those brands to ensure optimal performance.

Q: Where can I find an inventory of excavator parts for a Volvo excavator?

A: You can find an inventory of Volvo excavator parts at specialized equipment dealers or online marketplaces focusing on construction equipment parts. They often have a wide selection of parts, including standard and hard-to-find items.

Q: What should I do if I cannot find the part I need for my cat® excavator?

A: If you cannot find the part you need for your cat® excavator, consider contacting one of the parts specialists who can help locate the excavator parts you need. They may also assist in sourcing aftermarket alternatives.

Q: How often should I check and replace hydraulic oil in my excavator?

A: It’s recommended to check the hydraulic oil levels regularly and replace them according to the manufacturer’s guidelines or after a specific number of operating hours. Keeping the hydraulic system well-maintained helps ensure the longevity and efficiency of your excavator equipment.